"To Bit or Not to Bit. That's the Question"

On the Real Value and Challenges behind Digitalization, and How to Address Them!

What You'll Discover

- Why industrial leaders face the same existential tension as Hamlet; and how to resolve it

- The three deadly sins of industrial digitalization that doom most initiatives to failure

- How to build a Digital Decision Architecture that harmonizes thermodynamics with market dynamics

- An 8-step blueprint for moving from decision fragility to predictive clarity

- Why "analog managers" can successfully sponsor digital initiatives—with one critical shift

Act I: The Provocation

The Decision Fragility Tax

We can't "steal" the structure of the famous "To Be or Not to Be" without a respectful contextualization, so this post (most for my enjoyment than for your readability) will be split into Acts. Welcome to the first Act!

1. The Contradiction

In Hamlet, Act 3, Scene 1, the Prince faces the most famous question in literature: "To be, or not to be." In the context of the plot, it was presented as a question of life versus death, but in the end, it was a question of action versus paralysis. Hamlet argued that we endure the known suffering of life rather than fly to the unknown suffering of death, because "the dread of something after death... puzzles the will". I can't imagine a more solid parallel to this than our current way to manage industrial facilities and assets... you'll see!

Hamlet was deciding on his own fate, in the dark. He had no models. No simulations. No way to quantify the "undiscovered country". So, as a conclusion, he froze.

Today, industrial leaders face the same existential tension: "To Bit, or Not to Bit."

"Not to Bit": Ignore Digitalization.

Plant management based on anecdotes of past employment, decision fragility fueled by confusion and urgency, million-dollar expenditures as turnaround cycles based on intuition, thermodynamic constraints fully ignored until the noble equipment fails or catches fire just to trigger a new witch hunt, and the slow erosion of margin under the confused eyes of managers... BUT we have Excel and PowerPoints for everything...so we feel "OK!"...because this is known territory.

"To Bit": Embrace Digitalization.

The fear of supposed "complexity", the skepticism of a "digital theater", where the current own skills may not hold, and the very realistic worry that algorithms may (and will) violate the laws of physics itself allowed in our business infrastructure.

Most leaders, like Hamlet, consciously or unconsciously choose the known suffering. They, at their pure hearts, stick to spreadsheets, tribal knowledge, long meeting debates, and isolated studies, just because the digital alternative feels like an "undiscovered country", like "there, I don't feel I am at control as a manager!". Of course, this is carried inside their hearts as a "secret", as secret as other dark pleasures, because these days to be accepted or promoted to a manager, the "right" face to display is that of "I'm all about digitalization and AI!!", even if one doesn't have a clue about what that means...(i.e. What is an AI model actually optimizing, token by token, when it generates an output?")

Do you feel the "dramatic tension" now? Advocating for the unknown is commonplace nowadays.

But ...Is here where the analogy ends, and where your advantage, as an Industrial Manager, begins?.

Hamlet failed because he (as all of us) lacked data on the very specific topic of life and death. But you do not, because luckily our job, as Industrial Managers, is to decide on Industrial Assets that have never-ever killed anybody (Bhopal, Texas City Refinery, Piper Alpha and Chernobyl as just some examples for our tranquility!).

So, this blog entry (blueprint-wanna-be) is about Digitalization, but not about buying digitalization technology. It is about helping you to build a Digital-Decision-Making Strategy that feels realistic, comfortable and even attractive, so you can, honestly, open your heart to digitalization without faking (too much) with it, but truly know the new land you are entering.

With a proper understanding of Digitalization, the question is no longer "To Bit or Not to Bit", but When we start!

2. The Stage 1: "Faking it"

Every industrial leader today faces the same quiet crisis: You are asked to sponsor "digital transformation" while knowing, in your gut, that most of it is theater.

- Dashboards that don't decide.

- Algorithms that no one really understands, where many of those recommendations don't even respect the physics of your industrial process.

- Promises that don't survive the control room.

So, to be honest, all Digitalization projects start not by true digitalization but like more decision fragility dressed in bits. Do you truly believe the commercial representative of XYZTech.co has any clue on what is going on in your own manufacturing process, when your own engineers are still confused?

But there is a twist. Even as useless as it may look-like at the start, the "fake it" part allows some people to entertain the idea. "And, if we truly master this?", or "Hum. This may work if we stop, study, reach for help and make ONE thing real, one thing that works". And then, miraculously, out of a marketing hype we get people TRULY interested in study, research and understand what is all this thing of the digitalization about. And, hidden in those reflections, the first marvelous revelation appears.

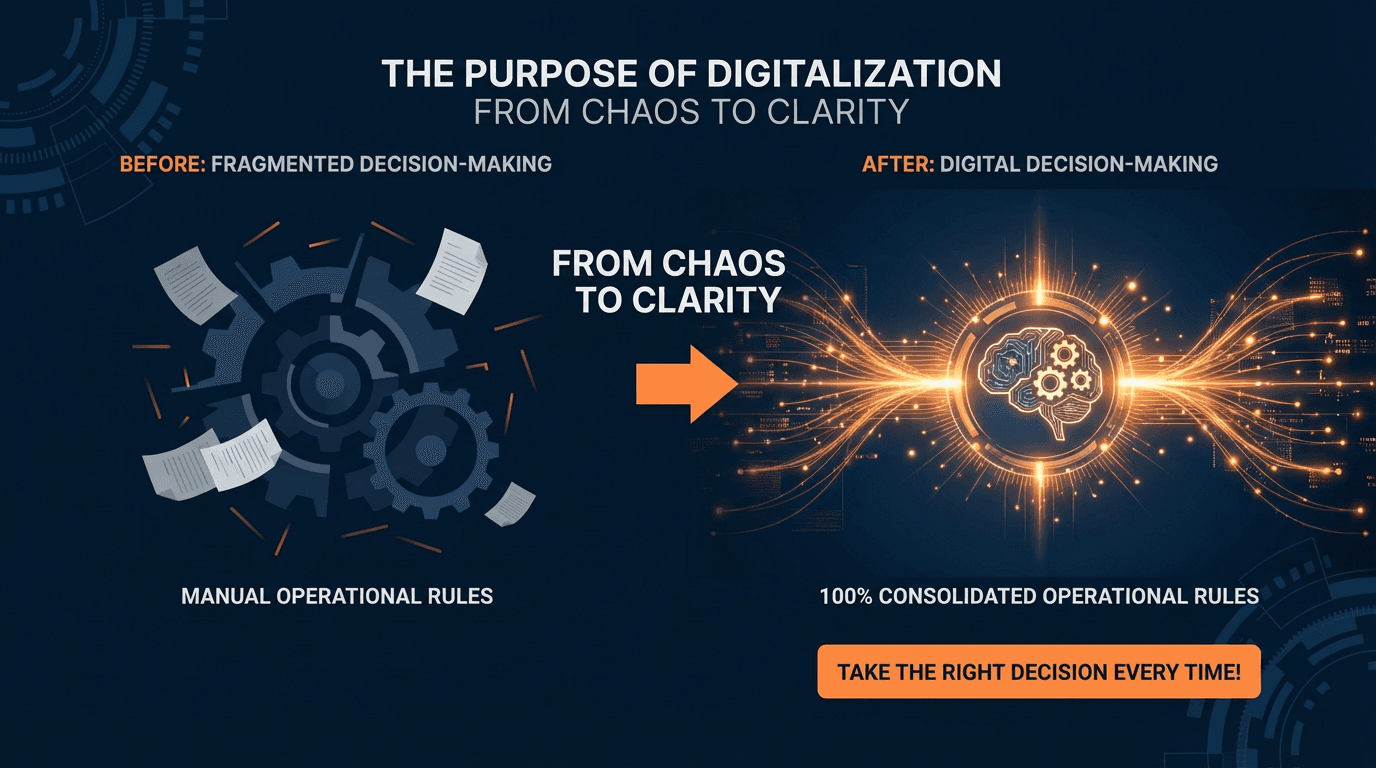

What are we Digitalizing?

• A pump? No, a pump with or without a sensor, is a pump.

• A control strategy? No, controls are (nowadays) by definition digital devices that operate on data even before you understand what a PID is.

• Decision-Making? YES. The Digitalization is the Digitalization of the Decision-Making! That is, the "before" and "after" in Digitalization Initiative must look different in the way you take the decision in your industrial corporation and your industrial asset, and the whole idea is that the Digitalization effort allows you to consolidate 100% of the Operational Rules of your asset and your business to take the right decision every time!

But wasn't it about putting sensors everywhere?: That is like saying that cooking is like putting salt or sugar here and there. EVENTUALLY you'd need to put some new instruments and technology, but FIRST the entire assembly of ingredients has to make sense. When we address properly a Digitalization project we are not fighting for having more sensors, but for getting closer to the holy grail of perfect decision-making (right and on time) every time and for every situation.

3. The Accusation: Three Sins of Industrial "Digitalization"

To move forward, in our dramatic presentation, we need the "antagonist", the "enemy" (the Claudius in the original Hamlet). We must name the enemy. Most initiatives fail because they commit to one of these demons:

1. Technology Over Logic

Buying sensors and dashboards before defining the decision. Visualizing data is not deciding.

2. Finance Over Physical Possibilities

Aiming to optimize ROI while fully ignoring thermodynamic constraints. A financial model can suggest "produce more". A thermodynamic model says "you cannot, the heat transfer limits are reached".

3. Prototype Over Operational Tool (and this is the worst)

Delivering "studies", not decision-engines, not instrumented-competences. But here the key to detect it is very easy:

- • If it sits on a consultant's laptop, it is a report.

- • If it runs on your server and guides your shift, it is an asset, a "Digital Asset!"

Transition: So what does "making it" actually look like? Let's move from accusation to architecture.

Is Decision Fragility silently eroding your plant margins? Let's talk about how to move from intuition to architecture.

Contact UsAct II: The Revelation

What Real Digitalization Requires

Revelation 1: We Don't Digitalize Machines. We Digitalize Decision Architecture.

There is a misconception that we digitalize assets. We do not.

What we digitalize is the Decision Architecture.

An Industrial Digital Asset (IDA) is the concrete embodiment of this idea: a computational platform that integrates:

- Process & Control Data Gathering (real-time operations, historians)

- Reliability, Performance & Degradation Physics (technical measurements, failure distributions, creep, corrosion, erosion, etc.)

- Market & Contractual Context (price curves, delivery obligations)

The result is (definitively) not a dashboard. We aim (in the language of MBSE) for "a single source of truth" that answers one question:

"In the current situation, what action maximizes business value across the asset lifecycle, given current physical constraints?"

In our experience working for leading organizations, in a regular project we mine over 30 - 50 million data points, we integrate hundreds of probabilistic models, and written thousands of lines of custom logic, and all that not because we want to "visualize a dashboard", but because we want the tool to explore and amplify diversity of future scenarios through simulation. Those simulations allow to convert questions into forecasts and such forecasts, when integrating all what is known about the business are the specific resource by which we support the decision making.

My very central point is that, if you:

- Digitalize the data flow from the equipment in the field to a real time database,

- Consolidate all the P&IDs and all the engineering information in one place.

- Purchase a solution for calculating Weibulls or whatever other probabilistic sorcery.

- Integrate all sort of functionalities for RCM, FMECA, RCA, RBI, KKK, etc etc and, install 74 AI tools BUT has no clue on how all that allows to improve the decision-making,

then you have accomplished nothing.

If you:

- Leave the decision architecture undefined or fragmented (before across spreadsheets and now across expensive tools),

- Allow for the "gut-feeling" and "long table/ meeting debates" to keep as the main decision scenario, where old anecdotes and tribal "knowledge" are used as the "de facto" decision tools.

- And, if every new decision doesn't make easier the next one,

Then you have only created a faster way to make the same mistakes, because digitalization is all about better chances to better decision in less time. If that's not achieved, then the investment is simply a failure.

Revelation 2: In "Asset Intensive" Business, Thermodynamics Is Non-Negotiable. Physics Beats Algorithms, Politics and Psychology.

This one is easy!. Let us strip away the titles. Plant Manager. Maintenance Director. Operations Lead, all these positions, in the end, have a core occupation identical to that of a bakery owner, a power plant operator, or a steel mill director.

Your work and main responsibility is to Harmonize Thermodynamics with Market Dynamics.

And this is not philosophy. It is the operational absolute of every industrial asset on earth. No matter how many "HR initiatives" you have, they are secondary to a perfect awareness of the thermodynamics of the business. Sometimes I see in client organizations 25 programs on how to become better "friends at work" and leadership, and that's marvelous IF you first mind the very critical amount of energy concentrated in your asset that can easily erase all that community from the planet. I know this is controversial, but managers in general tend to forget there is indeed a tremendous amount of energy and power trapped in the industrial asset. The fact that it's normally silent doesn't mean is less important than the workers associations fighting for their rights. The most responsible act of love you can have with your entire team is making sure you and your team are competent enough to face all the challenge such levels of energy can impose on your control capacity. What do you prefer, angry faces, or an undesired release of dangerous levels of energy and chemicals? Both are definitely important, but with the people you can negotiate. With the laws of thermodynamics you have to OBEY! (haters... proceed!)

So, In context:

- Thermodynamics answers: "Is it safe to do this?" Is there enough energy? Will the material creep? Is the risk acceptable?

- Market Dynamics answers: "Is it advisable to do this?" Is the margin positive? Is the demand real? Is the opportunity cost too high?

The Tragedy of Industrial Management is that these two forces are usually at war during the decision-making process, and it is exactly there where your Digitalization Initiative must support you:

- To maximize Market Value, you know some teams inside the corporation will ask you to push the unit harder (higher temperature, longer cycles).

- To maximize Thermodynamic Integrity, some other teams (more precisely those guys putting their own skin next to the asset) will ask you to slow the unit down (lower stress, frequent shutdowns).

Historically, managers have been forced to choose sides. The Technical Team protects the physics (sometimes even over-maintaining, killing margin). The Financial Team protects the P&L (often under-maintaining, risking failure and dreaming the business has an asset that is not really there).

The Result: Decision Fragility, seen as teams "debating" as if the market or the advance of creep or fatigue mind such long debates.

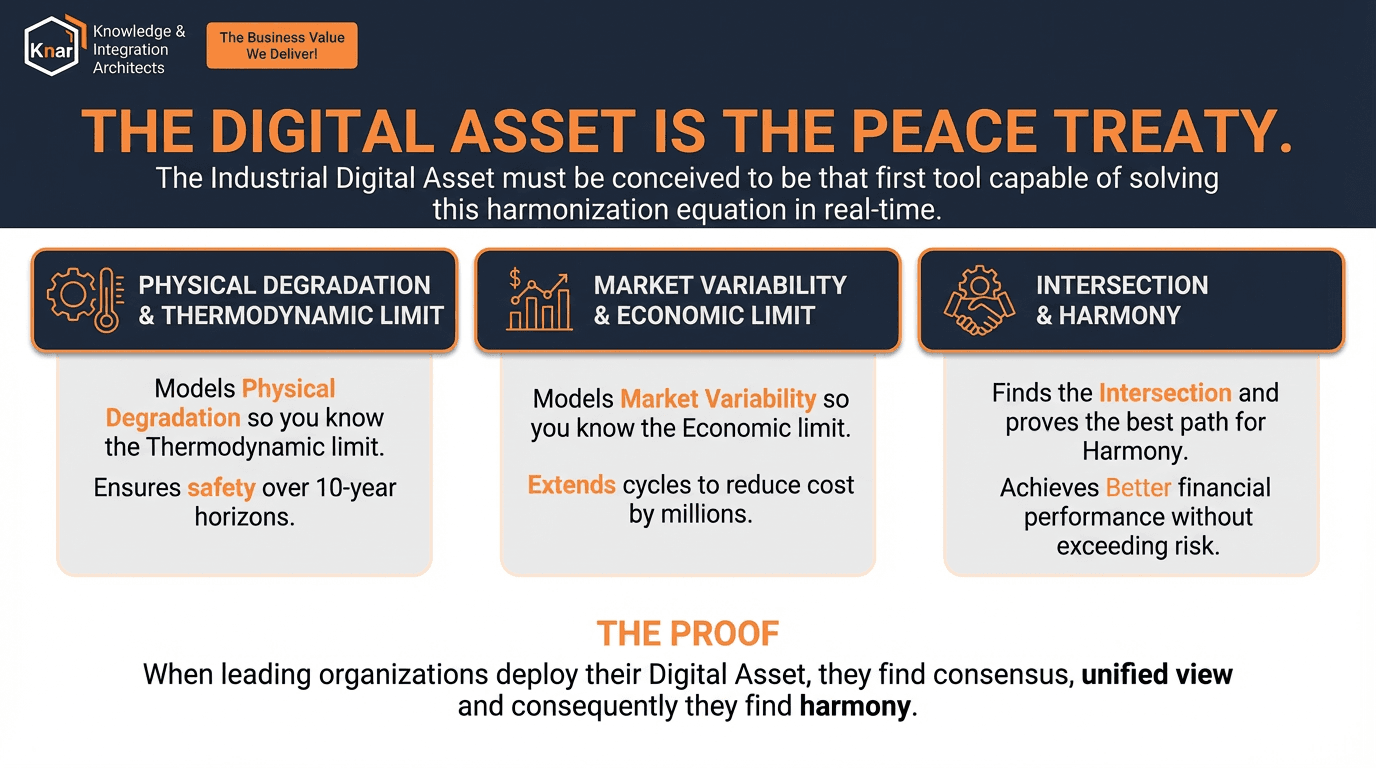

The Digital Asset is the Peace Treaty.

The Industrial Digital Asset must be conceived to be that first tool capable of solving this harmonization equation in real-time.

- • It models Physical Degradation so you know the Thermodynamic limit.

- • It models Market Variability so you know the Economic limit.

- • It finds the Intersection, and most importantly It can prove why that's the best path of action as per the information available.

The Proof: When leading organizations deploy their Digital Asset, they don't just find a better maintenance schedule or a better production plan. They find consensus, unified view and consequently they find harmony.

- Thermodynamics: A mature Digitalization initiative should be able to model risk across 10-year horizons, ensuring safety limits are respected even when extending operational cycles and integrating all the undesired event related to a plant not fully controlled.

- Market: A mature Digitalization initiative also identifies that extending a turnaround cycle by just one year can reduce total cost impact by tens of millions of dollars and increase cumulative production by significant fractional percentages. It is also aware of the market cycles and it can calculate the effective impact on cash of executing the turnaround in January vs in June.

- Harmony: Teams achieve better performance by cooperation, not by competition. Financial goals don't need to be seen as enemies of technical limits simply because a major event is very expensive, so everybody looking at the same picture generates agreement, not competition. It is not only possible to achieve Better financial performance without exceeding risk thresholds, simply because events and major events are crazy expensive!. The risk profile remains stable while profitability surges.

The power of cooperation between diverse teams it's also easily capitalized. In one recent implementation, data analytics revealed operational optimization opportunities (such as reaction temperature control vs. product yield) in the order of $10M/year—found not by trial and error in the field, but by simulating the physics against the economics in the digital realm, in an effort where technical teams and financial teams were all giving us the set of "business rules" they had learned about the asset and the surrounding context. Those 10 MUSD appear without adding any single sensor or database. It was money lying there, but hidden below 30 million of obstacles that needed to be properly addressed by Digital means; a task no way possible by human means, where digitalization demonstrated very clearly its value.

Revelation 3: Concrete Metrics, Honest Limitations, Iterative Validation

Credibility comes from transparency about limitations, not from overpromising. So, in case you are dreaming whatever software or simulation team will make everything to be all right magically, you'll be disappointed. These are going to be all right once you YOURSELF make them to be all right, and that implies using Digitalization to truly allow YOU to understand YOUR own business.

It is not the task of the digitalization platform to understand your business for you; That's your job.

Recent deployments have shown that risk projections can be limited by partial inspection data or outdated reliability baselines. Risk levels may appear artificially low if physical degradation models are not yet fully integrated, and all that are evolutive stages of a Digital Asset. Like a kid, Digitalization projects first lay there doing nothing but "sucking resources", then start to crawl, eventually walk and later run, faster than yourself!. That's the way it works. It's a well planned and coordinated evolution, not a hectic and magical revolution.

This evolutionary way is not a failure of the tool; it is a call to action for the manager. It means you must invest in the quality of your underlying data (RBI, maintenance histories, operational logs) with the same rigor you invest in the software itself. The Digital Asset exposes your data gaps; it does not hide them, so you have the option:

- A) Blame the new digital asset by not being perfect from the first time, or

- B) Understand the "massive levels" of knowledge synthesis and codifications required for the Digital Asset to truly act as a performing advisor.

It is up to you.

The Validation Rigor: Trust is earned through a "Three-Level Acid Test":

- Technical: Does the model behave as intended mathematically?

- Functional: Does it represent physical and operational reality?

- Managerial: Are leaders willing to act on its probabilistic outputs?

If any level fails, the model returns to refinement. This is not a bug; it is the methodology.

Want to explore how an Industrial Digital Asset could harmonize thermodynamics with market dynamics in your operation?

Contact UsRevelation 4: The Human Gap — Can a Non-Digital Manager Sponsor This Type of Effort?

Well...and here I am incarnating the very Claudius for you, dear reader. Here comes the most uncomfortable question.

Can a "Analog Manager" who became a Manager using "the ways of the analog" before the digital age, be a great sponsor for Digital Initiatives?... (uncomfortable pause) Well, I don't know. What is known is that only when an analog manager admits what they don't know, there's a chance for the initiative. Otherwise, the Digitalization Project would be a dead man walking. The reason is clear for me (after hundreds of hours with my clients around the world). It's easy to see managers applying "analog" thinking to digital projects. You see easily the discomfort of being a leader sitting in the middle of a meeting where nothing makes sense because even the language is different. It's a personal option to take:

A simple test is the delivery of results:

- Analog: Single-point estimates ("This will save $2M") → Hides risk, invites failure

- Digital: Probabilistic forecasts ("There is a 90% confidence interval of $1.5M–$2.8M savings, contingent on feedstock volatility") → Enables robust decision-making

So, of course I am not defending confusing jargon, but I do defend to level the language and the thinking completeness to the level of complexity of the interaction of these two complex processes: The thermodynamics of the plant, with the Dynamics of the market. This is NOT a matter of unduly oversimplification or a case where, because "I am the manager and I am too busy, you have to explain it to me simpler that it really is". It is, on the contrary, a situation where "I am the (Digital) manager, and as so, I must be able to see and face 100% of what is in there, no matter if it is complex and no matter if I am happy or pleased" (More of this in the next FANTASY MOVIE from Pixar ;). )

Act III: The Resolution

Practical Guidance for Leaders Who Want to Make It

The Distilled Blueprint: 8 Steps, 3 Iterations, 1 Mindset

In summary to succeed in a Digitalization initiative, we need a "cognitive shift". Not "brave claims" not, "motivations speeches", not artificial "over-simplification by magical softwares", but serious and mature development of cognitive skills able to match the promise of the Digitalization project. Here is how to reorganize your thinking on Digital Decision Making:

| Phase | Core Question | Critical Check | Success Signal |

|---|---|---|---|

| 1. Define | What high-value decision are we enabling? | Thermodynamics + Market Dynamics alignment | Decision-focused scope, not technology deliverable |

| 2. Diagnose | Where are our gaps in people's attitude, data, tools, culture? | Are we measuring the right physics and market signals? | Prioritized roadmap, not wish list |

| 3. Model | Does our base model reflect physical/ commercial reality? | Can it reproduce historical events within error bounds? | Technical validation sign-off |

| 4. Integrate | Can we trace sensor data to P&L? | Are physical limits hard constraints in the optimization? | Causal map from component to EBITDA |

| 5. Validate | Do we trust it? | Tests. Three-level sign-off: Tech/ Functional/ Managerial | Willingness to act on probabilistic outputs |

| 6. Refine | How do we improve? | Are new physical insights and market factors incorporated? | Increased fidelity + usability, not complexity |

| 7. Transfer | Who owns this tomorrow? Is this a project owned by the consultant, or by the company? | Are internal teams certified to run/update the model? or, on the contrary "People is too busy to learn the new ways" | Capability survives personnel changes |

| 8. Scale | How do we go from unit to fleet? | Can we simulate cross-unit dependencies? | Enterprise resilience, not local optimization |

Critical Note: Steps 3–6 are cyclical. Expect 2–3 iterations before operational trust is achieved.

Cognitive Shifts: Reorganizing the Mind for Digital Decision-Making

From "Data First" → "Physics First": Your asset doesn't care about your database. Also the market, so focus on what is important FIRST!. Start with mass/energy balances. Then ask what data is needed and go from there taking full control of the physics/ thermodynamics happening in your plant. As true laws, Physics laws can only be obeyed. There your negotiation capacity is, by the way the laws of our universe work, exactly zero!

From "Automation" → "Augmentation": Be realistic and don't really rely on human behavior when something need to be 100% in control. Humans can be the most valuable control layer, but they can't be the 100% of the layer. Automate repetitive monitoring (high human entropy); augment exception handling (high human intuition).

From "Project" → "Living System": An Industrial Digital Asset is not a "deliverable" or a Report ending the end date of the consultant contract. It must be shaped as a "organizational capability" that learns. As whatever pump in your plant, a Digital Asset must work (and power point reports don't work).

From "Recommendation" → "Traceable Logic": Use causal mapping so every error discovered and every suggestion can be audited. Trust requires consistency and transparency. Of course the first version of your Digital Asset won't be a perfect one, but have the potential none of your ad-hoc activities has, the potential to grow and have a corporate wide scope.

From "Single-Point" → "Probabilistic" Thinking: Embrace probabilistic thinking, confidence intervals and all the new machinery of Digitalized Comprehensive thinking. Oversimplification is the enemy of robust decisions, so if you don't get it at the beginning, well, take a book, study, improve your own "communication capability" by learning how to express performance and risk measurement in comprehensive formal terms....IN other words...Study?... What's the problem with that?.

Respect Time Constants: Market signals change in milliseconds; reactor temperatures change in hours so conceive a proper intensity of work at every level of digitalization. By truly understanding physics and market dynamics you'd know where to put more resources and effort to truly track changes and improve constantly your decision making.

Sponsorship Requires Curiosity, Not Coding: If you are the sponsor, be curious, be adventurous, cancel all your former ideas of what is possible and what is not. In the Digital Words, many impossibilities of the analog behavior become irrelevant. Be Open. In the end, as a sponsor, you're not going to code a single Line ;)

Ready to build your first 90-day digitalization blueprint? We can help you identify the right first decision to digitalize.

Contact UsFirst 90 Days / First 2 Years: Action Plan for Leaders

| First 90 Days | First 2 Years |

|---|---|

| Validate your Digital Asset against all the historical events of relevance (production, turnaround and market events) | Scale your Digital Asset methodology to 3 additional units |

| Certify 2 internal engineers as "Digital Asset Practitioners" | Establish corporate Integrated Decision making governance forum |

| Automation Example: Automate PI historian data ingestion for one critical loop for variables criticals to safety and profitability. | Automation: Integrate market price APIs for real-time margin optimization of the multi-unit Digital Asset |

| Run the "Three-Level Acid Test" on your current digital initiative | Interconnect unit-level ADIs to simulate business-level scenarios integrated with the market |

| See the demon to the eyes! Host a "Decision Fragility" workshop with your leadership team | Institutionalize Digital Asset use in CAPEX reviews and turnaround planning |

Closing: Bits That Respect Heat

In the end, the drive for transformation has such a power that "To Bit or Not to Bit" was never the question. The bits are inevitable. The real question is: Do our approach to bits respect our thermodynamics, illuminate our market dynamics, and empower our decision architecture?

Whether you run a refinery or a bakery, you are playing with mass and energy to support societal needs, so embrace fully the completeness of the situation with the aid of Digital Means, and cancel once and for all the addiction to oversimplifications.

- If you ignore the Thermodynamics, the asset fails (no bread, no gasoline, and maybe no more industrial asset).

- If you ignore the Market, the business fails (no profit, no society).

And of course you can't ignore your teams, but be wise in picking the battles.

The laws of nature are NOT open for negotiation, the laws of team work, on the contrary, give you more room to negotiation, so solve first things first!.

Your job is not to "manage people". Your first responsibility is to keep them alive and allow them to better do their work to create a safe and profitable relationship in the triad Physics/ Market/ People.

Start with one decision. Build one initial version of your Industrial Digital Asset. Validate it rigorously. Transfer the capability. Scale with discipline. That is how you move from decision fragility to predictive clarity.

Bits that respect heat are not just data. They are value and safety for your team and for the society so, sponsor the change and advance!

Discuss Your Digital Decision Architecture Project

Ready to move from decision fragility to predictive clarity? Let's talk about building an Industrial Digital Asset that harmonizes your thermodynamics with market dynamics.

Schedule a Consultation